Suzuyo's Fortes

The six fortes why Suzuyo Kogyo is chosen

-

Introduced by more than 1,000 companies

A pioneer in natto production equipmentThe very first company in Japan in developing automated equipment for natto production with more than 50 years of experience and achievement.

-

Providing a comprehensive full-line service

By virtue of providing a comprehensive service from planning, designing, manufacturing, installing to maintenance, we are able to foresee the next process and pursue the quality.

-

Excellent integration ability as an independent multi-vendor

We are able to implement the most suitable and ideal combination of machines, utilizing their strong points case by case regardless of manufactures.

-

“One-stop” maintenance service

When a breakdown occurs, Suzuyo Kogyo Co., Ltd. is able to be a support counter for the repair of all kinds of machines.

-

Providing the best practice for natto production based on abundant experience and knowledge

Not only do we install machines but we also give complete guidance and trainings for production.

-

Realization of short delivery / starting up

a manufacturing plant in a short period of timeWith abundant engineering logic based on longtime achievement, we are able to construct high-quality equipment in a short period of time.

If you have any challenges regarding food production,

please feel free to contact us

Suzuyo Kogyo’s

Full-line Service

Suzuyo Kogyo Co., Ltd. is able to provide a "Comprehensive Service with One Step Approach"

-

01Planning

01Planning- Consulting, Product planning, Concept designing, Application procedure support, Support on selecting plant locations, Calculating return on investment, Product design

-

02Designing

02Designing- Field investigation, Machine selection, Reference drawings for construction, Layout plans for equipment, Creating work schedule, Providing trial calculations on personnel arrangement, Simulation

-

03Manufacturing

03Manufacturing- Manufacturing machine, Developing automatic control devices, Maker control (delivery time/ quality), Contractor control (electricity, construction, and others), Quality/ Performance control, Building time/ work schedule control, Project management

-

04Testing

04Testing- Machine performance testing, Trial operation of machines, Production process combining testing, Tuning, Performance optimization, Machine configuration adjustment, Operation plan testing

-

05Trainings

05Trainings- Creating manuals, Providing guidance on how to produce products, Giving guidance on quality control and hygiene management, Providing trainings on how to maintain machines, Creating training materials, Giving guidance on how to comply with regulations and ordinance

-

06Maintaining

06Maintaining- Performing machine maintenance, Conducting on-site maintenance, Videophone support, Performing an overhaul, Repairing/ Reconditioning/ Remodeling, Adjusting/ Tuning, Giving an examination on next equipment for remodeling

Suzuyo Kogyo's

Total Service

- Planning

- Designing

- Selecting Machines

- Manufacturing and Installing

- Production Guidance

- Machine Maintenance

-

Raw Material Processing Equipment

-

Bean Washing and Soaking Equipment

-

Cooking Equipment

-

Fermentation Equipment

-

Packaging Equipment

-

Automated Lines

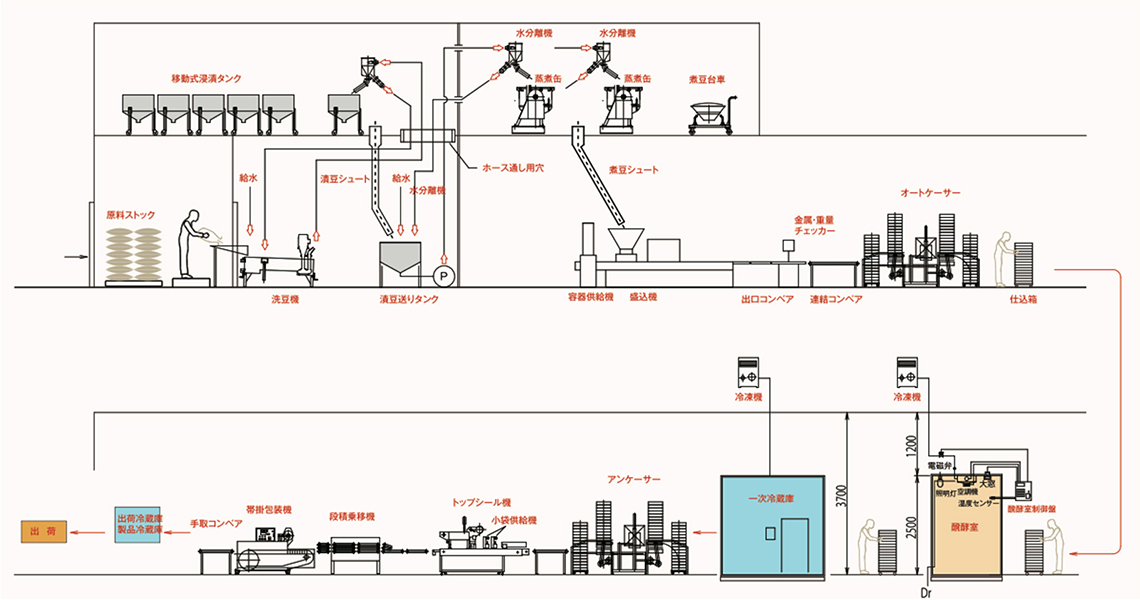

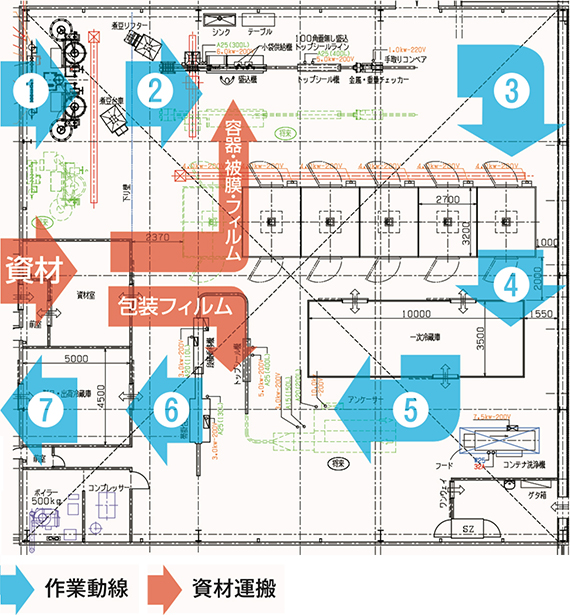

Providing knowhow on designing manufacturing plant and

the most ideal coordination on plant layout

Based on long year abundant experience and knowledge, Suzuyo Kogyo Co., Ltd.

provides the most effective and optimal plant layouts while maximumly taking the employees' operation route into consideration.

- Example process for natto production Bean Washing and Soaking

- 01Feeding soaked beans into cooking pot, utilizing the second floor Cooking

- 02Feeding cooked beans from cooking pot to filling machine Filling

- 03Placing packed natto into fermentation chambers Fermentation

- 04Moving fermented natto to the primary refrigerators Maturing

- 05Conveying matured natto to the secondary packaging machine Secondary Packaging

- 06Placing packaged natto into the secondary refrigerators Stock yard

- 07Through docking terminal, the products are shipped by trucks